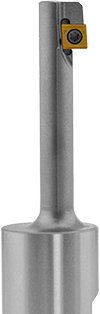

Back counterboring

Reverse boring bar RBU

- new RBU replaces the old RBS+ more information here

- For spotfacing, chamfering and deep counterboring of areas with difficult access

- RBS+ is very stable and rigid with surface treatment and FEM-optimized geometry

- Internal coolant for RFS and RBS+ starting from d=18

- Wide choice of different PCD-, carbide- and HSS indexable inserts

- The new RBU offers a much higher stability due to the optimized cutting edge position

- For requests of specials

Reverse counterbore system TU

- Manually operated reverse machining

- Universally applicable on all machine types

- Flat bayonet for quick and reliable manual tool changes

- Large cutting width (up to 2.5 D)

- Multiple regrinds are possible

- Several diameter combinations of counterbores and holders

- The same basic holder (TUHW) plus adjusted guide sleeves (TUB) can cover several guidance diameters

Autofacer AFA

- customized special design according to your needs

- Easy and safe activation by inertia of flywheel when fast reversing the spindle rotation

- Automatic (forward and) backward spotfacing, counterboring, chamfering

- Big cutting width (up to 2.2×D, from D1 = 12.5)

- Applicable on all machines with fast accelerating spindle

Do you already know our full product range?

We are your competent partner for:

drillinginsertscounterboringshrink fitback counterboringspecial request