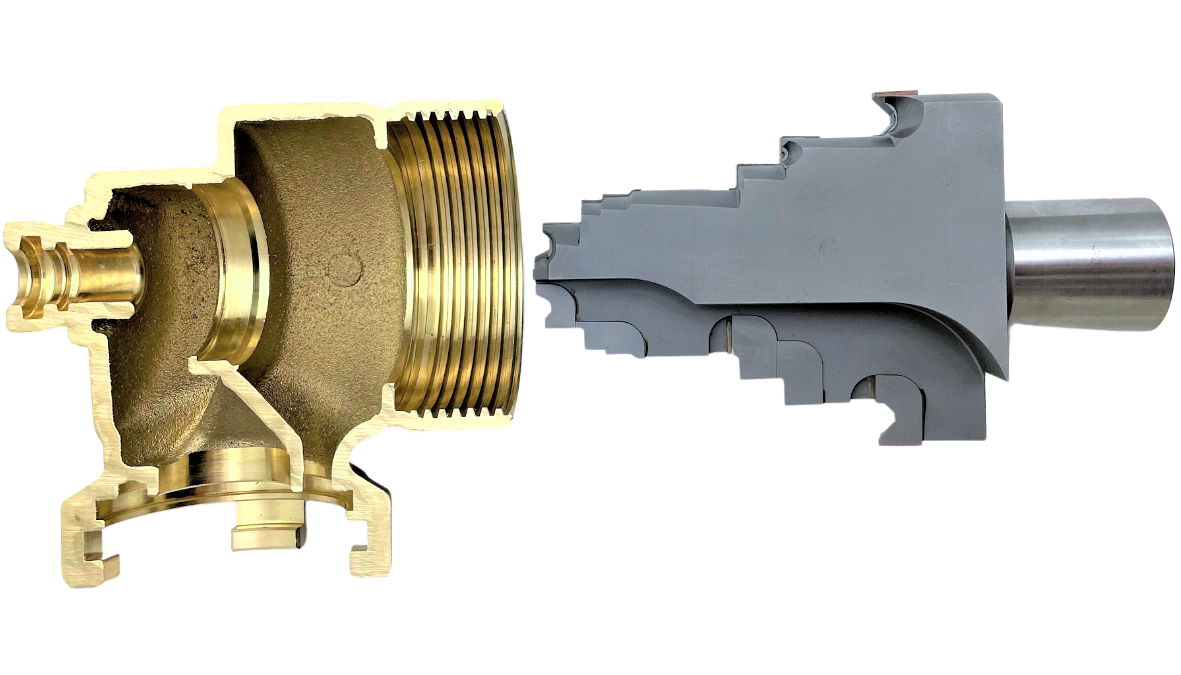

The challange

Pre-machining the entire inner and outer contour of the brass water filter housing requires maximum precision. However, the switch to lead-free brass brought undesirable changes with it. The longer chips and burr formation on the outlet contours present new challenges that require efficient machining methods. Overcoming this problem requires innovative tool solutions to ensure high-quality finishing and product quality.

The Bilz solution

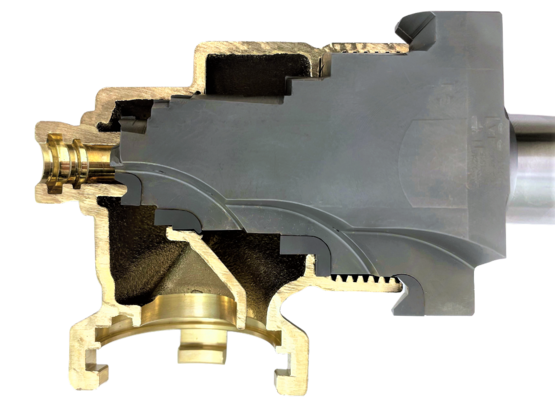

Special stepped counterbore:

With brazed carbide cutting edges and positive cutting edge geometry adapted to the application, this tool solution ensures short chips and burr-free bore edges.

The result:

Burr-free workpieces without separate deburring mean efficient machining without additional work steps. This solution enables complete machining with just one tool, which not only saves time but also costs. Thanks to optimized cutting edge geometry, our solution produces shorter chips and thus enables production to run smoothly and without machine interruptions. These advantages not only support precision, but also optimize production processes in the hydraulics industry.

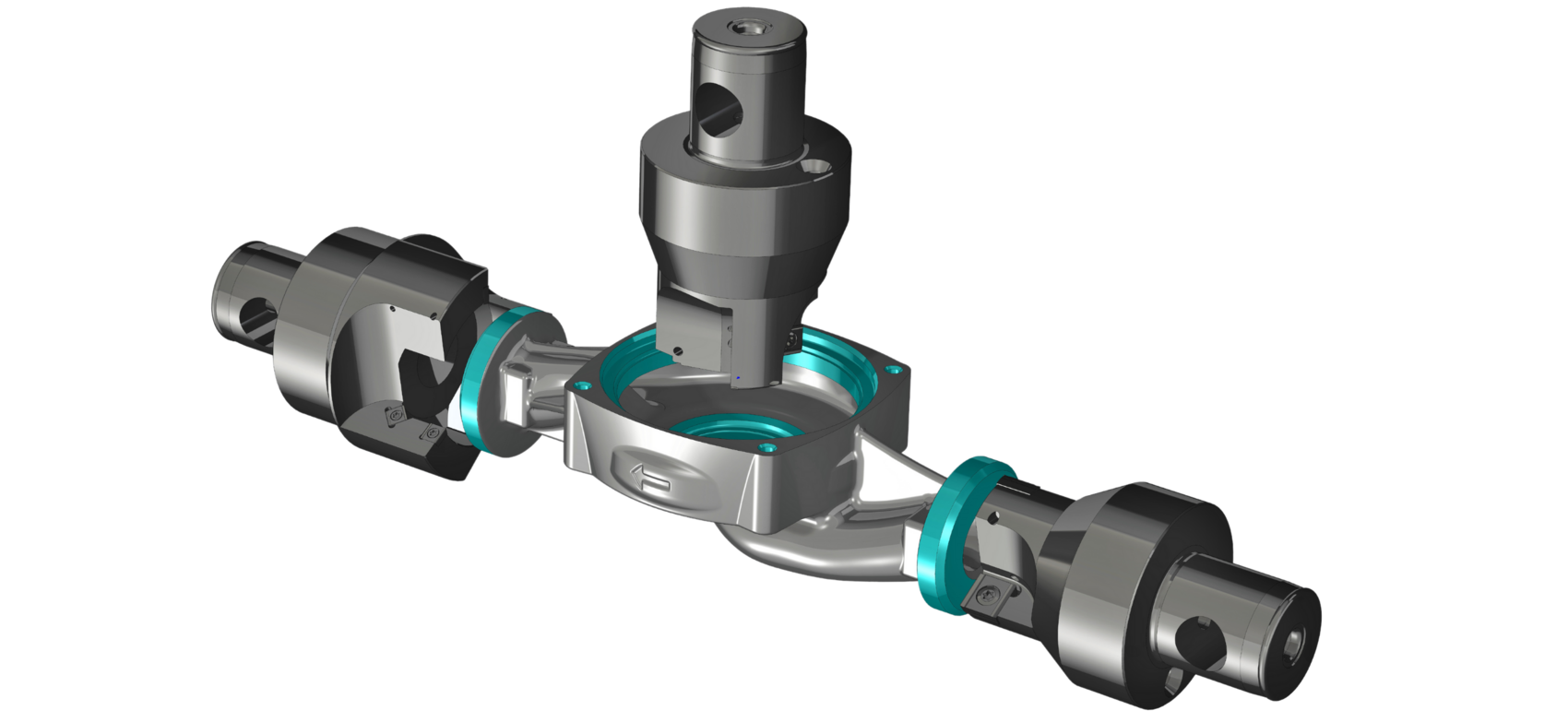

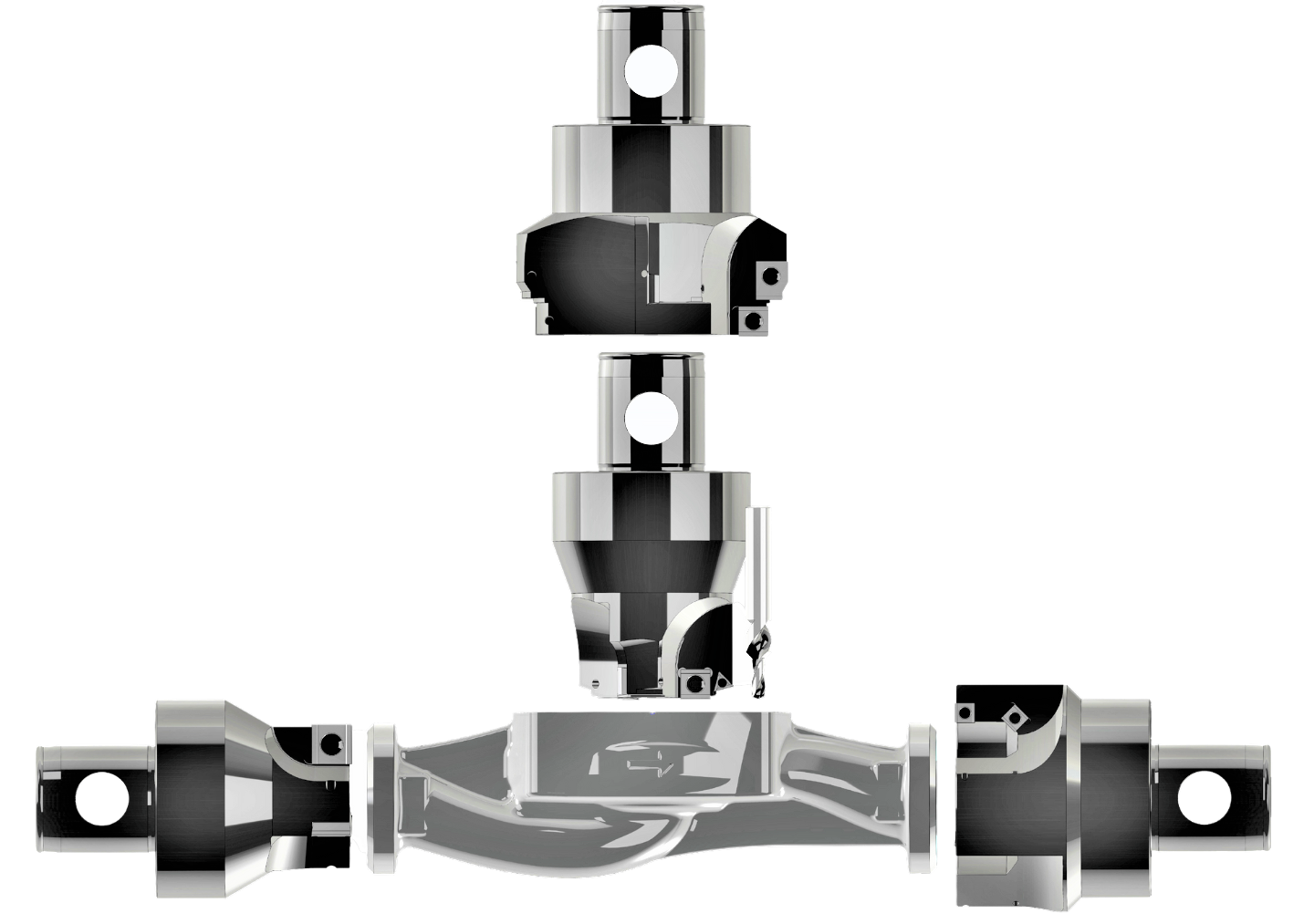

The Bilz solution

Multi-stepped boring and counterboring tools with standard and special-shaped indexable inserts produce the internal and external contours with just one or a few multiple-point tools, thanks to high cutting data in the shortest possible time.

The result:

Complete machining with a small number of tools offers decisive advantages. The use of high-performance tools with multiple cutting edges significantly reduces the machining time. Special shape indexable inserts also enable the precise shaping of even narrow steps and complex contours. These innovative solutions not only optimize efficiency, but also precision in production.

Solid-carbide stepped boring-tools and reamer

Our strength is in the development of customized solutions for complex contours. We offer multi-edged tools that are equipped with internal cooling and can also cut across the center if required.

Coatings or PCD tipping are also available as options. The reconditioning of tools after use is of course part of our service to guarantee continuous precision.

Special indexable insert tools

For hydraulic fittings, especially in control blocks, we offer special shaped inserts. These inserts are equipped with chip breakers and can produce the entire sealing surface contour, including the transition radius, in a single step. If required, it is also possible to divide the contour into several standard inserts. This flexible approach enables precise and efficient production according to individual requirements.

Solid carbide form-cutter

Our solid carbide form milling cutters are specially developed for the precise free milling of valve guides. They are equipped with numerous coated cutting edges and several steps, which ensures fast and reliable machining. These high-quality tools enable the efficient production of valve guides with outstanding precision.