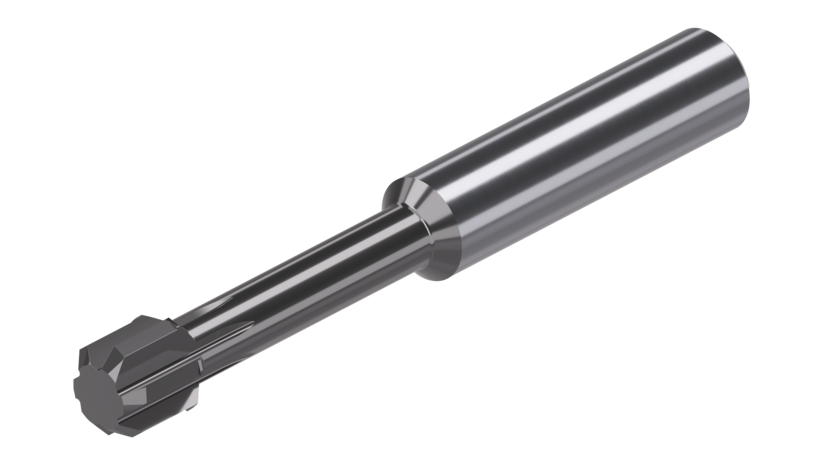

Reverse boring bar micro RBSM

Standard range

-

Spotfacing Ø 6,5-15 mm

- Ideal for cylinder head screws DIN 912 from M3-M8

- Made from solid carbide for maximum rigidity

- Counterbores up to 1.9 times the bore diameter

Special designs

- Any diameter combinations

- Modifications available at short notice

- Radius option

- Also available as chamfering bar with freely definable chamfer

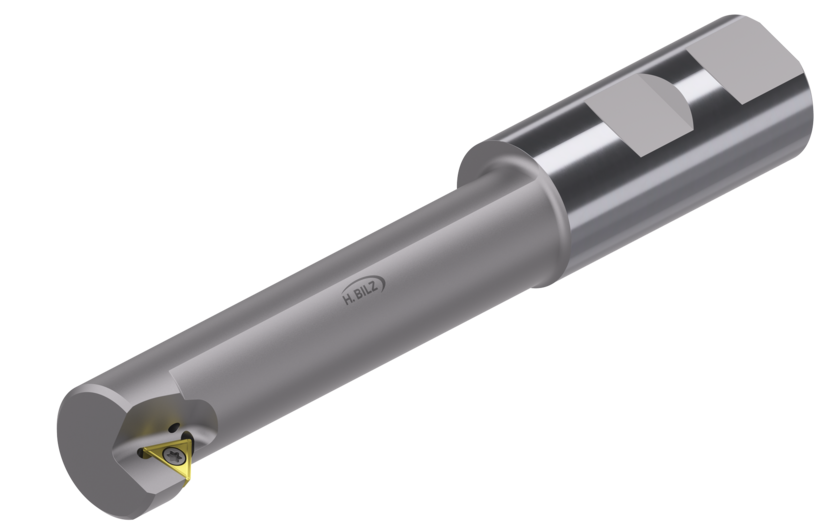

Reverse boring bar RBU

Special designs

- Any diameter combinations

- Adjustable insert seat for fittings

- Modifications available at short notice

- Any customization of the insert to the application

- Heavy metal design

- Multi-step design possible

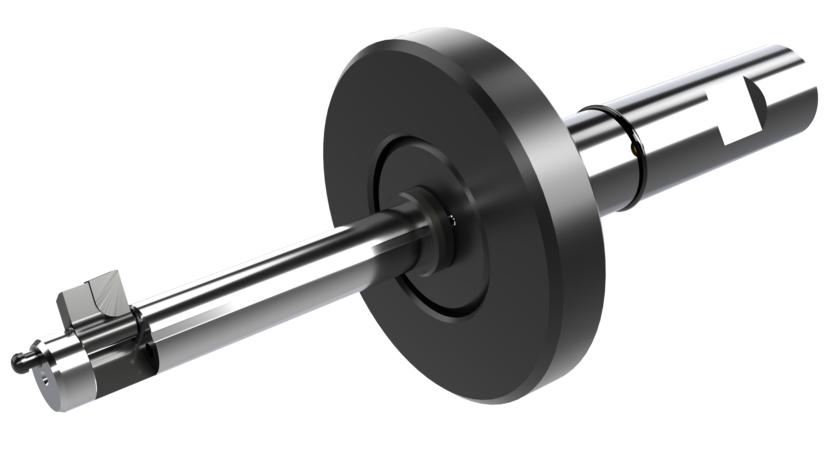

Autofacer AF

Standard range

-

Spotfacing Ø 9.5-33 mm

-

For drill holes Ø 6.5-15.5

-

Usable length up to 50 mm

-

Internal cooling from guiding-Ø 9.4

-

Brazed cabide cutting edge

-

Mechanically controlled opening and closing by flywheel

-

Counterbores up to 2.2 times the bore diameter

Special designs

- Any diameter and length combinations

- Customization of the insert fitting the application

- Adjustable insert seat for fittings

-

Indexable insert option

-

Customizable double cutting edge for forward & reverse machining

- Modifications available at short notice

-

Various activation mechanisms (e.g. bump style, torque bar, etc.)

-

Ideal for interrupted cuts

-

Edge postion sensoring system

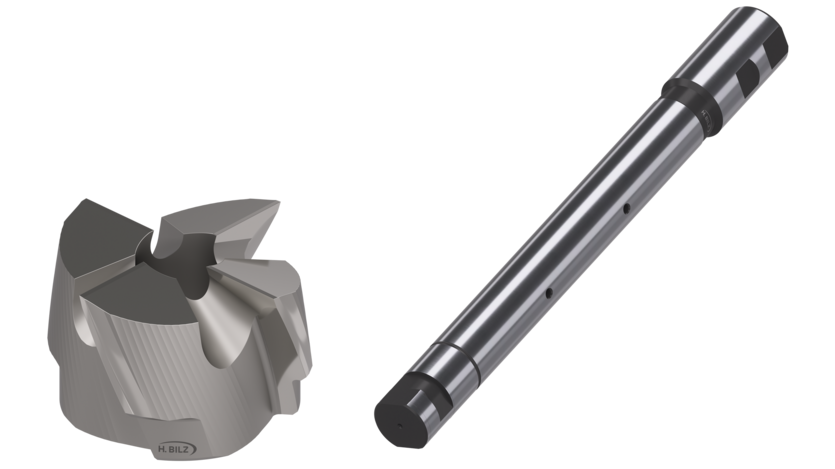

Reverse counterboring system TU

Special designs

- Any diameter combinations

- Can also be designed as an insert version

- Modifications available at short notice

- Any customization of the cutting edge geometry

- Holder with lubrication grooves

- Multi-step / special shapes

Reverse chamfering bar RFS

Standard range

-

Chamfering Ø 15-31 mm

-

with internal cooling

- Significantly better rigidity thanks to optimized cutting edge position

- Large selection of indexable inserts

Special designs

- Any diameter combinations

- Modifications available at short notice

- individual chamfering angle

- Any customization of the insert to the application

Chamfering cutter FUN

Standard range

- Deburring on both sides from a bore diameter of 3.3 mm

- High wear resistance thanks to X-CEED coating

- High toughness due to fine-grained carbide

- Dry and wet machining

- Machining time reduced by 80% to 5 sec for 4 chamfers!