Drilling into solid

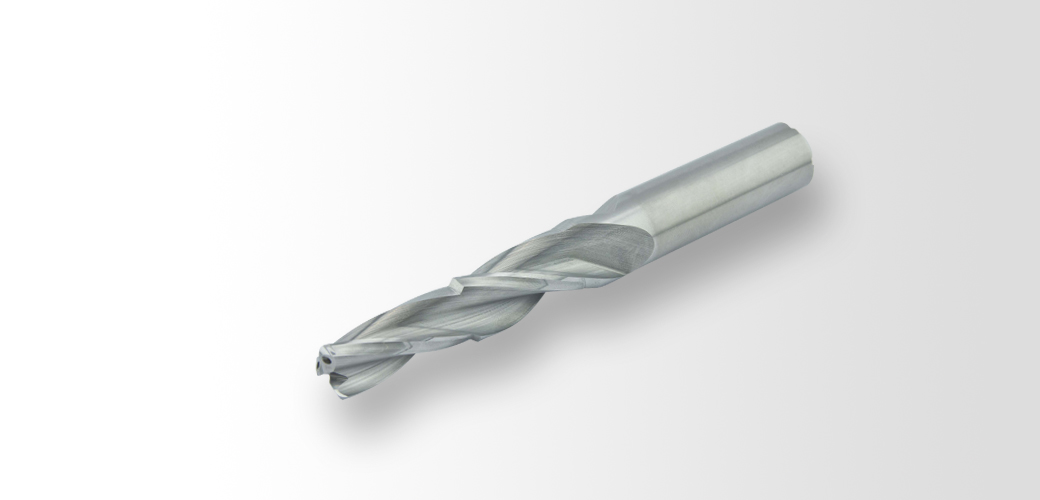

Turbo-Drill

![[Translate to Englisch:] Turbo-Drill](/fileadmin/_processed_/2/2/csm_Turbo-Drill_hermann_bilz_a48e6b9f41.png)

The new high-performance drill for all common steel grades! The Turbo-Drill combines maximum process safety with significantly increased productivity and reliability.

- Four cooling channels provide optimum cooling of the entire cutting edge

- Chamfered cutting edges significantly increase stability

- The polished chip chamber ensures smooth and fast chip evacuation

- Four guide chamfers improve the circularity of the hole

- Coated drill tip provides increased durability and tool life

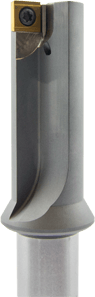

KSB-Powerbore

The insert drill with teeth!

- For holes between Ø 39-160 mm

- Self-centering by means of core cutter

- High toughness in the centre

- Also suitable for stacked bores

- High feed rate due to maximum overlap of inserts

- Very positive rake angle for low machine power requirement

- High performance by rigid and undivided holder

- Close drilling tolerances (H11)

- Straight bores due to guiding chamfers on the external inserts

- Guide plates for inclined bore outlets and cut interruptions (KSB03)

- Universally usable with carbide and HSS-inserts

- Also usable in unstable conditions

technical data configure nowsee the Powerbore in action!check machine requirements

Flexispeed

- For holes between Ø 18-39 mm

- Self-centeringby means of core cutter and symmetrically positioned indexable inserts

- High toughness due to HSSE-core cutter in the centre

- Hihg feed rate with two inserts

- Close drilling tolerances (H11)

- Straight bores due to guiding chamgers on the inserts

- Universally usable with cabide and HSS-inserts

- Also usable in unstable conditions

- Machining of stacked bores possible