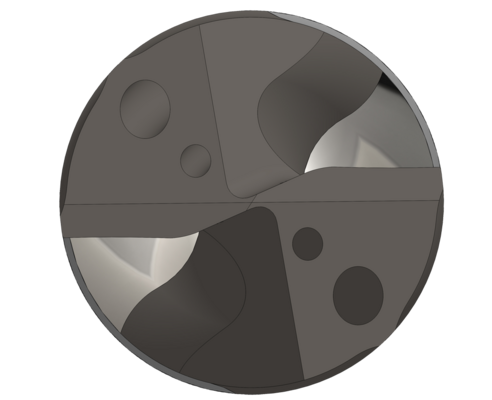

the new Turbo-Drill

the all-rounder for your steel drilling

Through discussions and active cooperation with customers, various applications in the field of steel machining were found by the research and development department of Hermann Bilz, which showed potential for improvement and whose optimization was promising. In close cooperation with these customers, the Turbo-Drill was therefore developed to optimize the use cases.

these features distinguish our Turbo-Drill:

- Four cooling channels provide optimum cooling of the entire cutting edge

- Chamfered cutting edges significantly increase stability

- The polished chip chamber ensures smooth and fast chip evacuation

- Four guide chamfers improve the circularity of the hole

- Coated drill tip provides increased durability and tool life

These influential factors result in a drill that can be used for high-strength steel cast materials (up to 48 HRC) and for high-performance drilling in all common steel grades. The Turbo Drill thus combines maximum process safety with significantly increased productivity and reliability. As a purely custom-made product, the Turbo Drill is always precisely adapted to your needs and can easily master even complex applications, e.g. with step(s).

You would like to get a better impression of our new Turbo-Drill? The 3D PDF makes it possible! Click here and experience the drill interactively in 3D.

Note: The 3D PDF cannot be displayed in the browser, please download the PDF and open it via Adobe. You also need to trust the document and then click in the PDF to view the 3D model.