select your product group:

Please select your preferred machining method based on the features listed below:

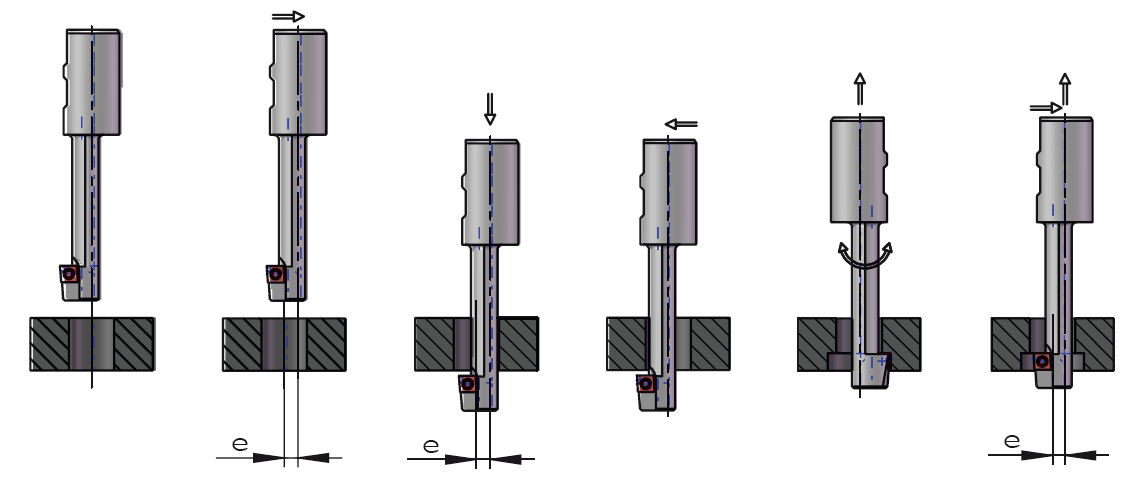

TU-System

Rückwärtssenker

- Customizable, also for intermediate dimensions

- Manual reverse machining can be used universally on many machine types

- Flexible handling for small batches

- Countersinking and boring

- Large cutting widths up to 2.5 x d

- Wide range of possible combinations of countersink and guide diameters

- Quick and safe manual change of the countersink due to flat bayonet

- Can be re-sharpened several times

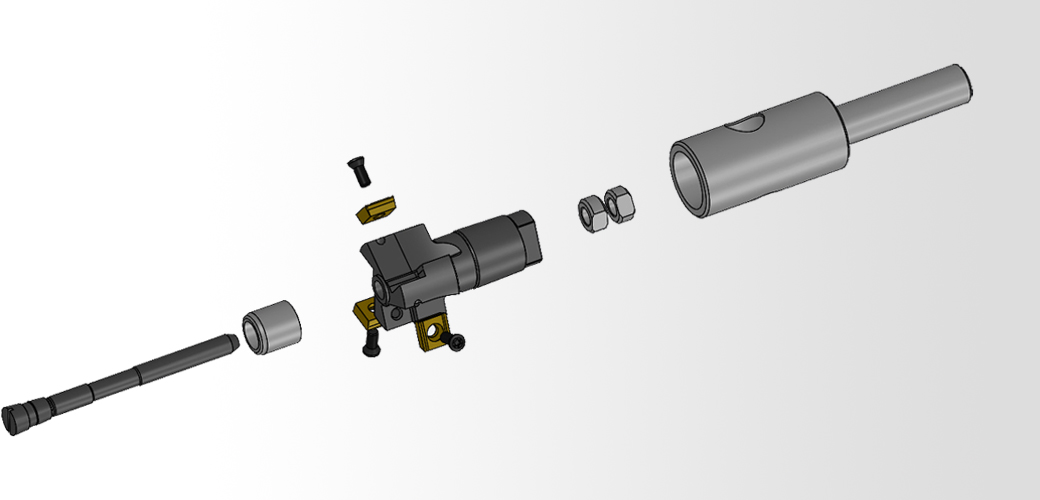

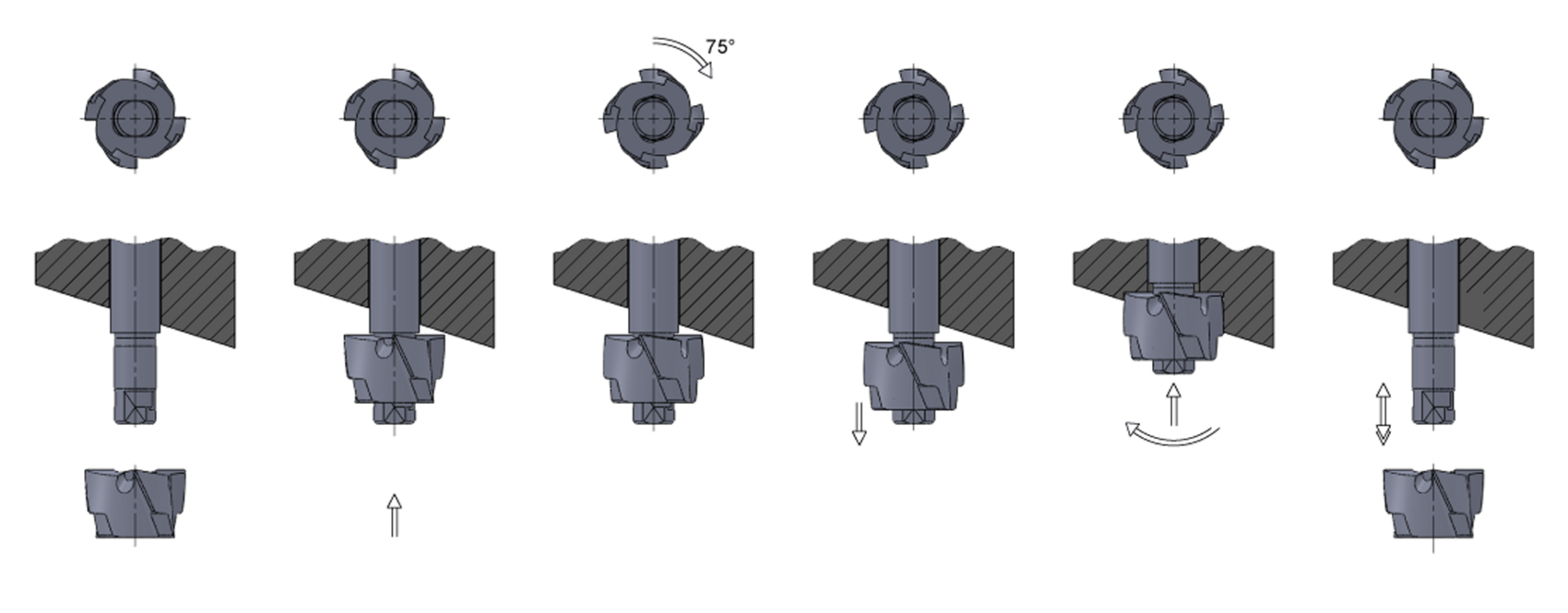

R5B / RBU / RBSM

Reverse boring bar

- automatic machining for medium to large production batches

- for spotfacing, chamfering and deep counterboring of areas with difficult access

- for counterboring up to 1.9 times the boring diameter

- usable for many materials due to a wide choice of different PCD-, carbide- and HSS-indexable inserts

- internal coolant for RBS+ starting from Ø18

- RBU offers a much higher stability due to optimized cutting edge position

- large E-modulus of solid-carbide RBS-Micro (RBSM) ensure max. stability

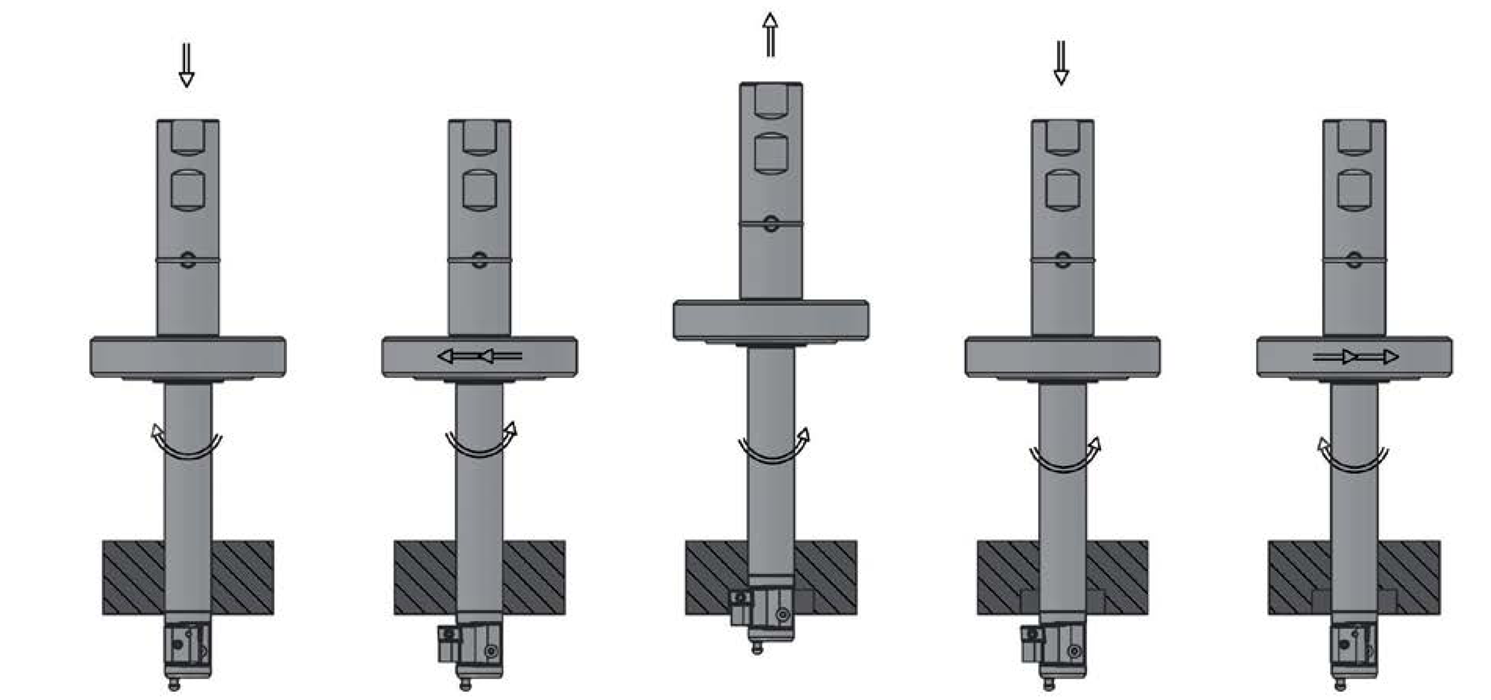

Autofacer

AFA

- customized special design according to your needs

- automatic machining for mass-production

- high reliablility and safety

- forward and backward machining possible

- large cutting width up to 2.3 times the boring diameter

- Autofacers are designed individually for each specific application

- lean design avoids collisions