Information for Bilz-cones

Criteria for Bilz-cone size selection:

The Bilz-cone-fixing connects tool and holder positively. That means, the transmittable torque depends on the cone diameter, respectively the Bilz-cone size. As the cutting-torque depends primarily on the cutting width and also on the material and cutting data, the biggest available Bilz-cone size should be chosen for heavy loads.

When machining with limited space in the workpiece, attention must be paid to the holder outer-diameter. In such cases a smaller cone diameter should be selected to ensure that the holder diameter is smaller than the tool diameter. This improves the chip flow too.

Features of the Bilz-cone connection:

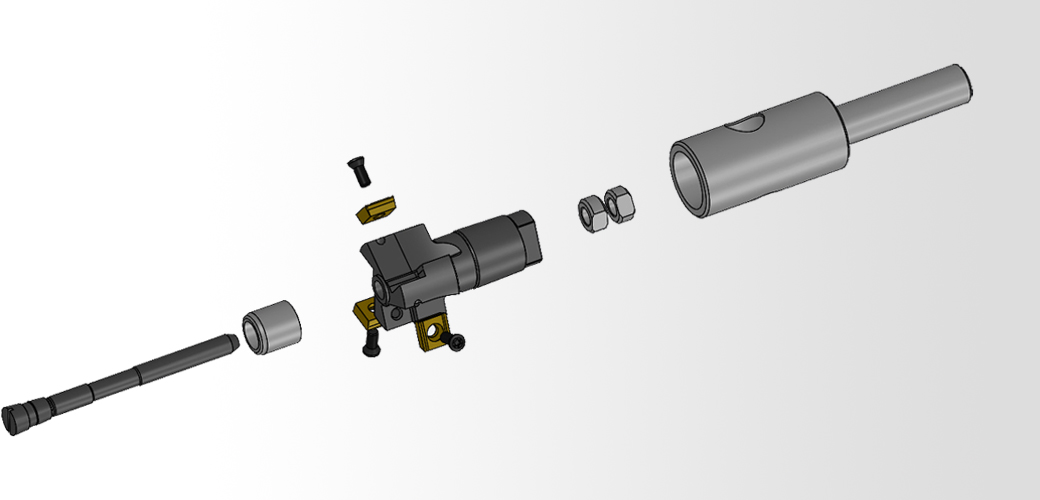

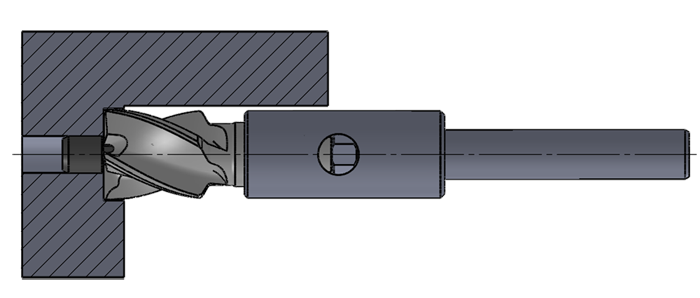

The Bilz-cone shank in combination with the Bilz-cone collet of the holder is a tight intersection with a high run-out-accuracy. It is particularly appropriate for drilling and boring operations, in which the cutting forces, especially the thrust tightens the link between tool and holder. For heavy oscillating radial loads (milling, counter boring with one-sided cut without pilot), the cone-connection is less suitable. Tool and holder can be assembled simply without using a mounting tool. The tool can be disconnected from the holder by using an extractor. For this it is fed into the cross hole of the holder until it touches the extractor tang of the cone shank. By turning the extractor, the tool is moved forward and disconnected from the holder.

The lean design of the Bilz short-cone holder is a special advantage over intersections with straight shank, locked by a side lock screw, like Weldon and Whistle Notch. Thus it is possible to combine conterbores with smaller holders.

Pilot assembly:

For Bilz-cone-size 1 and larger, pilot-sets consist of

- one- or two-parts pilot (depending on diameter)

- two screw nuts, and

- a soft washer as protection for the carbide cutting edges.

Before mounting it with the counterbore, nuts must be disassembled (for HSS- and AW-counterbores the washer too). Grease pilot, feed it into the bore of the counterbore, screw both nuts and tighten them against each other, so that the pilot still has a slight axial clearance (0,1) and can rotate in the counterbore. Please check that pilot diameter is larger than the minimum cutting diameter D2.

Information for securing

Tool-securing in the holder:

When used in automatic operations, tool and holder should be secured by a connector (extractor closer or -pin) and two set screws in the holder, to avoid unintended loosening. Similarly the HB-holder itself should be secured in the collet by the thread in More-Taper shank.

When using counterbores wihout pilot, the extractor pin, which is usually mounted in HB- and HBS-holders, is taken off after untighten the set screws in the holder, and screwed into tool-shank. The counterbore with mounted extractor pin will then be locked by the set screws in the holder.

When using counterbores with pilot HB, items in the holder-bore must be removed. The extractor closer HB (with internal thread) will be mounted on the pilot HB in the tool, free of clearance, and then be locked by the set screws in the holder.