RBU - our new standard series

Reverse boring bar RBS-Ultra

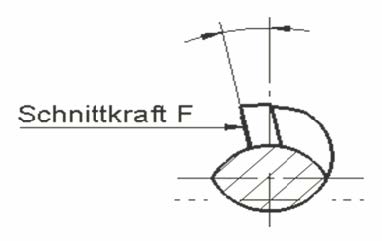

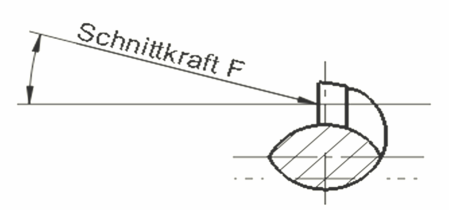

The new back counterbore generation RBS-Ultra offers a much higher stability compared to the previous RBS + version. The cutting force acts now in the direction of the largest neck cross section due to the optimized insert position. The result is that the cutting edge deviates less during machining. Furthermore we will have a significantly better dimensional stability and surface quality. In numerous particularly critical applications with extreme overhang lengths, large diameter differences and oblique countersinks, this version, previously known as RBS ++, has already ensured safe machining. The automatical RBS-Ultra can be used in many critical cases and will replace some manual back counterbores. The use of expensive heavy metal to increase the bending stiffness of back counterbore may not be necessary in some cases.

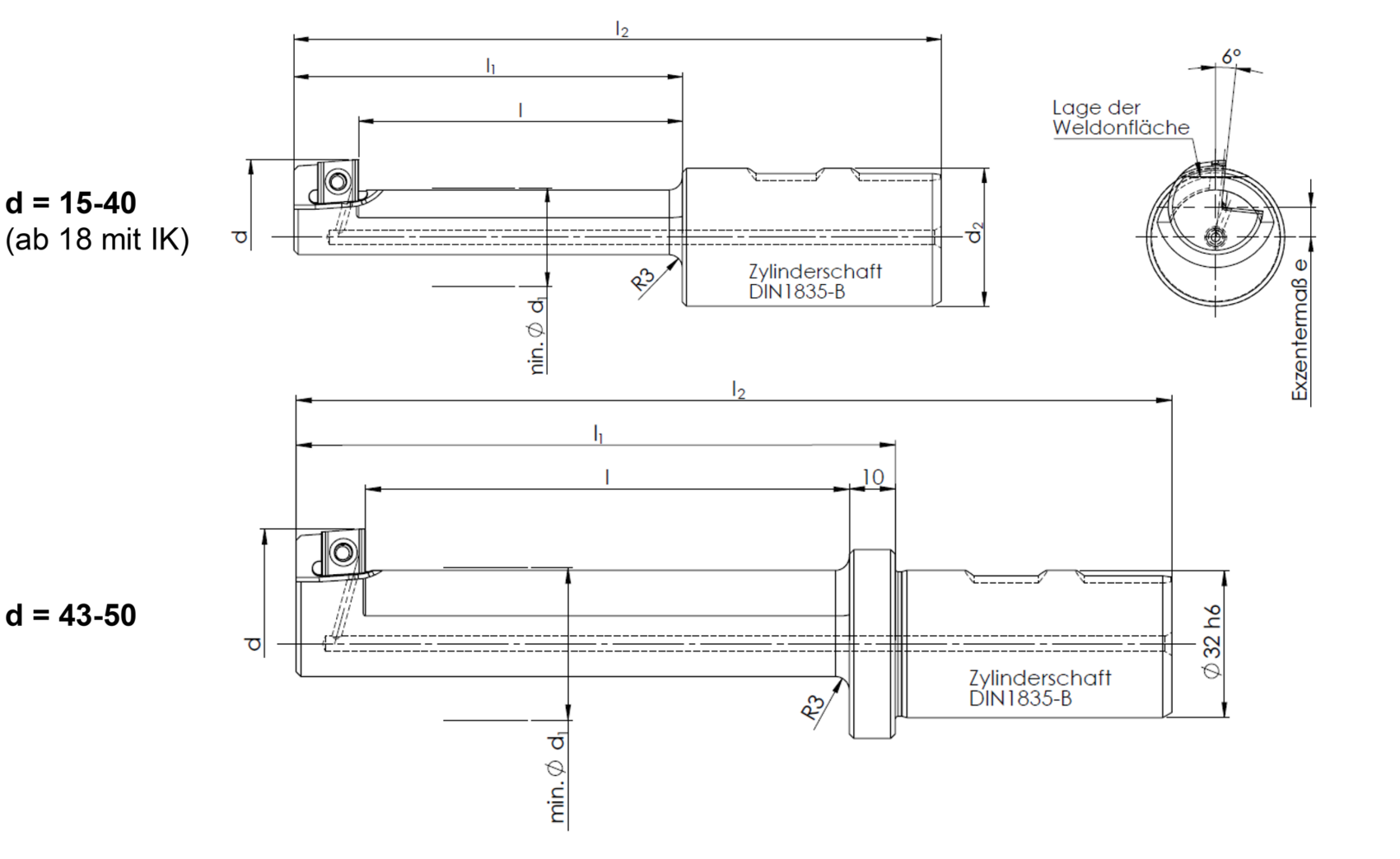

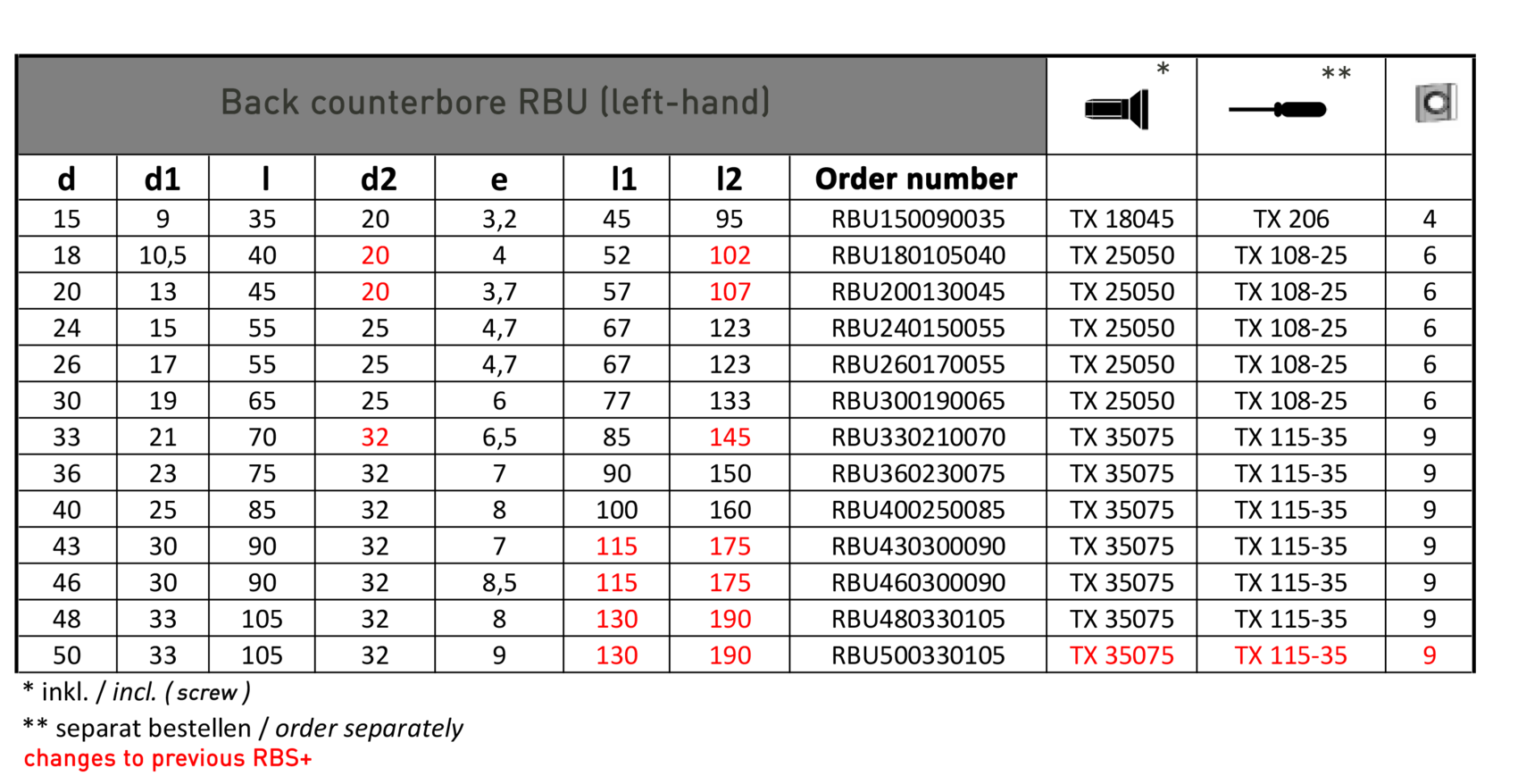

This new generation of tools is now available as the "new" standard series RBS-Ultra for back counterboring from diameters 15 to 50 mm. With optimized geometry, precision machined from high strength tool steel and surface treated, the RBS-Ultra range is far more powerful and durable than similar tools from other manufacturers

The RBU reverse boring bars are available now and will be the new standard from May 1. In addition to the cutting edge position, the shank diameters, the shank design (partly with reinforcement collar) and the lengths have changed for some dimensions. The effective lengths, however, remain unchanged. For d=50, the insert has been replaced by a smaller insert. Otherwise, the previous inserts can still be used.

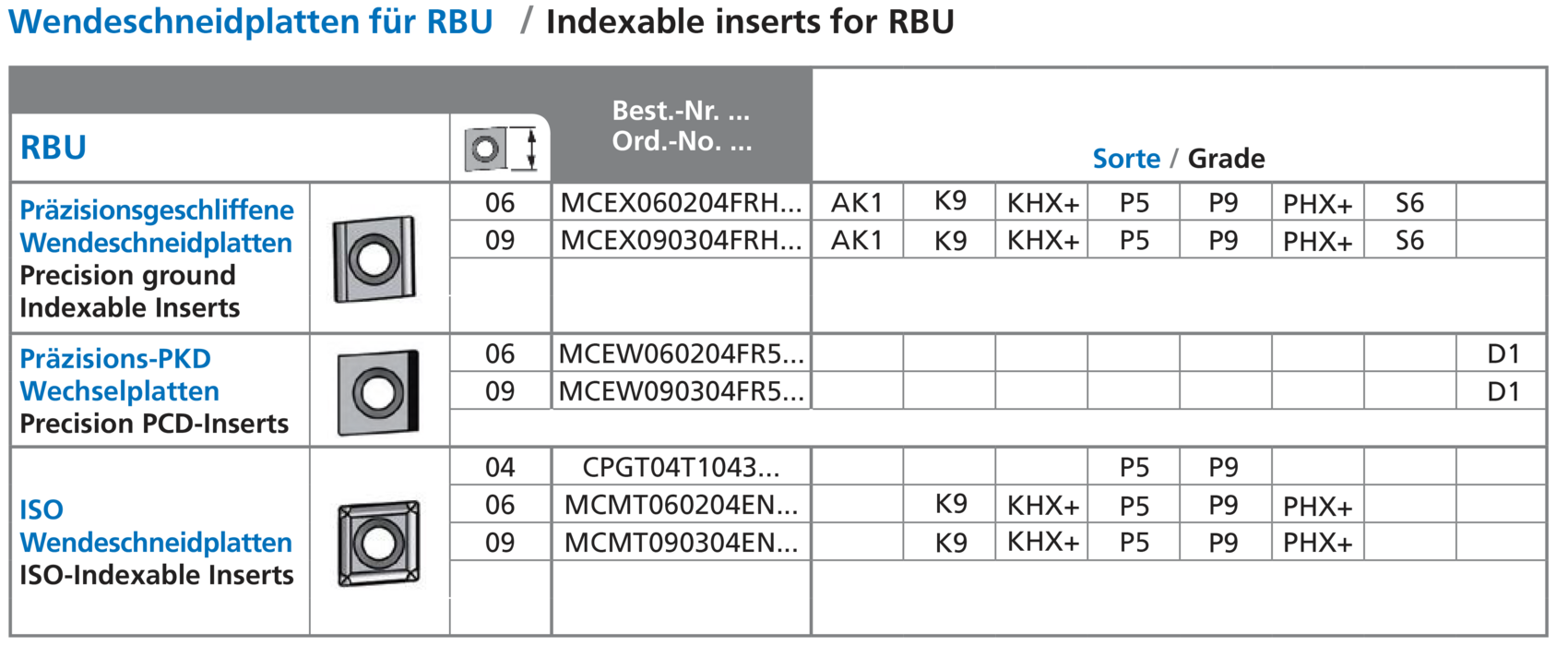

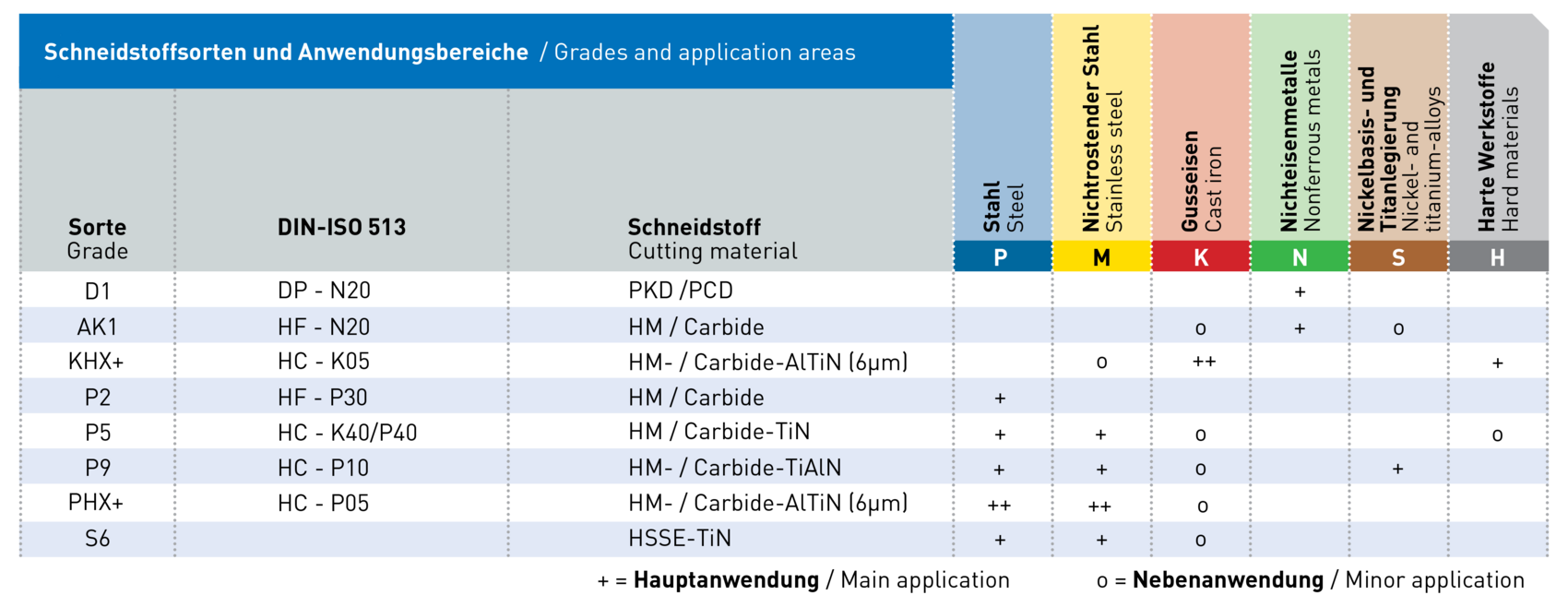

Also new is the internal coolant supply from diameter 18, so that now all tools except for d=15 ensure reliable cooling of the insert. Suitable inserts in various carbide, HSS and PCD designs can be found below or in the catalog.