Back counterboring and back spotfacing in hard-to-reach bores

With back spotfacing tools and back-counterboring solutions from Hermann Bilz you machine hole back faces safely and efficiently without turning or rechucking the workpiece. Whether you need back spotfaces, back chamfers or back deburring in hard-to-reach locations – our back spotfacing bars, Autofacer tools, modular back spotfacing systems and back chamfer / deburring cutters deliver stable processes and short cycle times.

As a technology leader with standard and engineered-to-order tools, we support you from tool selection all the way to a customized design for your specific components and volumes.

What do we mean by back-side hole machining?

In back-side hole machining the tool is first guided through an existing bore and is then opened and engaged on the back side of the part to create spotfaces, chamfers or to deburr. This makes it possible to produce seating faces for screw heads, sealing faces or chamfers on the back side of the component without reclamping or turning the workpiece.

This technology is ideal for hydraulic and pneumatic manifolds, engine and transmission housings, valve bodies, flanges and complex housings, where hole back faces are difficult to access. The result: higher process reliability, reduced setup and changeover times and lower cost per part.

Benefits of back-side machining with Hermann Bilz tools

Our systems let you fully exploit the advantages of back-side machining:

- Elimination of workpiece turning and additional setups

- Stable processes even in small and deep bores

- High dimensional accuracy and repeatability on hole back faces

- Internal coolant supply and optimized chip evacuation on many systems

- Wide standard portfolio plus cost-effective custom tooling

- Support from our application engineering team – from initial design to series production

Tooling systems for back counterboring at a glance

For different bore sizes, part geometries and production volumes Hermann Bilz offers six coordinated tool families:

- Back spotfacing bar Micro RBSM – back spotfacing in small diameters

- Back spotfacing bar Ultra RBU – rigid back spotfacing for medium to large diameters

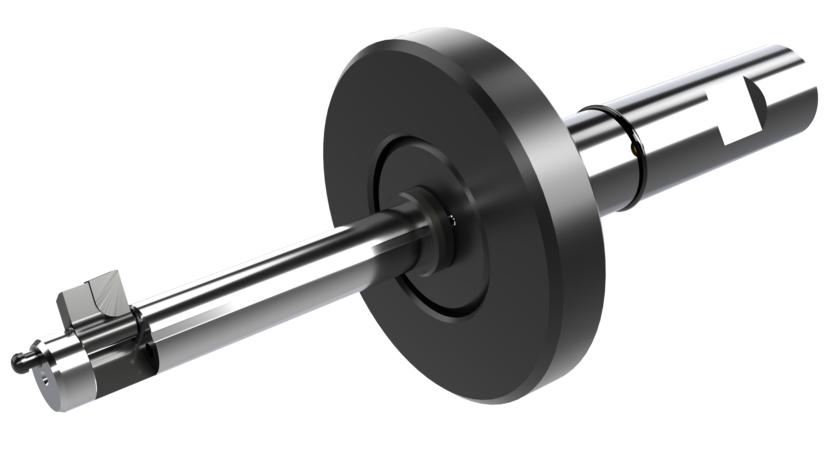

- Autofacer AF – automatic back spotfacing and back chamfering for high-volume production and large diameter ratios

- Back counterboring system TU – modular, manually actuated system with a wide diameter range

- Back chamfering bar RFS – back chamfering with indexable inserts and internal coolant

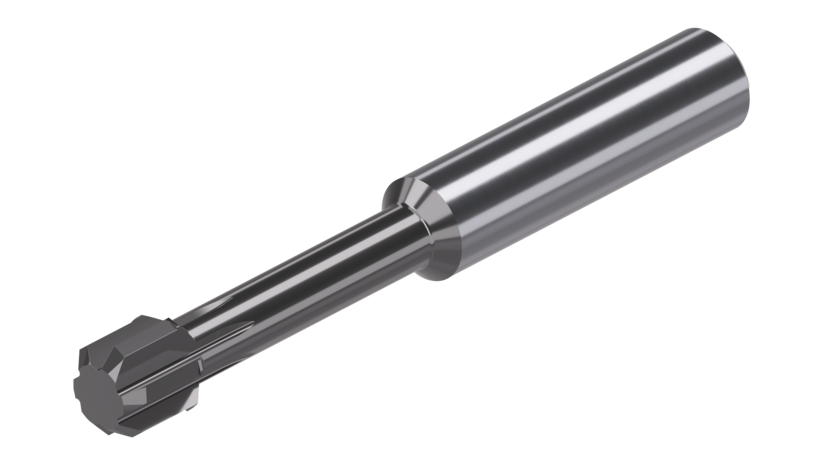

- Chamfermill FUN – double-sided deburring starting from very small bore diameters

Typical applications for back counterboring

Our back-side machining and back spotfacing systems are used in, among others, the following industries:

- Automotive: spotfaces and chamfers on engine and transmission housings, flanges, pump and control housings

- Mechanical engineering: back-side sealing and seating faces in housings, flanges and structural components

- Hydraulics / pneumatics: deburring and spotfacing of cross-holes and through-holes in valve and control blocks

- Powertrain and energy technology: components with deep and hard-to-reach bores

- General plant engineering: wherever hole back faces must be machined stably and with high process reliability

Engineering, design & standards

For optimized reverse machining, we take into account bore geometry, material, machine, clamping equipment, and required tolerances. Our application engineering team supports you with:

- Selection of the suitable system (Micro RBSM, Ultra RBU, AF, TU, RFS, FUN)

- Tool design, including cutting material, coating and cutting data

- Coordination with relevant standards and specifications (e.g. screw seats according to DIN 912)

- Documentation for your quality assurance

The more complete your information, the faster we can provide you with a suitable tool recommendation.

The solid carbide RBSM is specifically designed for back counterboring in the small diameter range and enables precise back spotfacing on hole back faces. It is ideal for compact components, small housings and hydraulic/pneumatic parts where small screw seats have to be produced on the back side. In addition to the standard range, we manufacture custom diameter combinations, radius profiles and back chamfer bars with freely defined chamfer angles – including short lead times for modifying existing tools.

Back spotfacing bar Micro RBSM

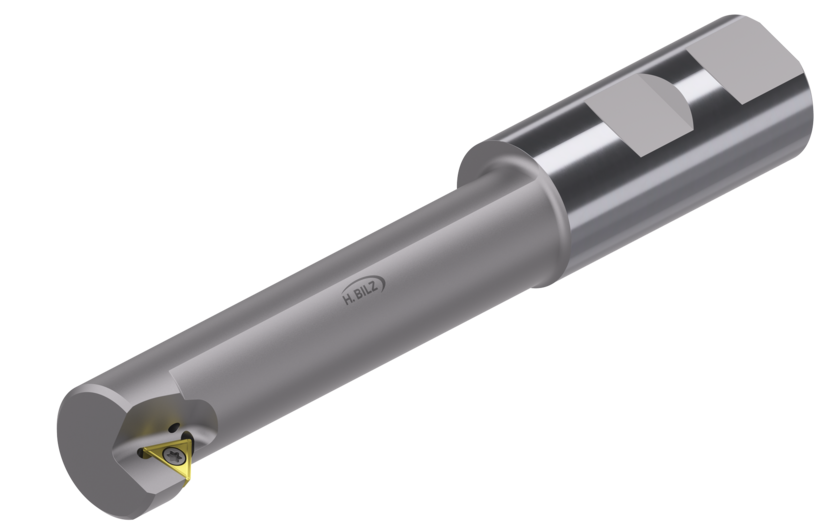

The RBU is designed for back spotfacing in the range of Ø 15–50 mm and offers significantly increased stability thanks to an optimized cutting edge position, especially for larger diameters and longer reach. The RBU is ideal for larger housings, flanges, and components with larger screw dimensions. Custom designs with adjustable insert seats for fits, heavy metal designs, multi-stepped geometries, and customer-specific indexable insert shapes complete the range.

Back spotfacing bar Ultra RBU

The Autofacer AF is an automatic back spotfacing and back chamfering system for hole back faces, optimized for high-volume, series production. Typical applications include engine and transmission housings, valve and pump housings and other components with high part counts. Engineered options include indexable-insert versions, double-acting tools for forward and back spotfacing, different actuation mechanisms (e.g. bump style, driver, torque arm) and sensor systems for monitoring the cutting edge position.

Autofacer AF

Custom designs

- Any diameter and length combinations

- Customization of the insert fitting the application

- Adjustable insert seat for fittings

-

Indexable insert option

-

Customizable double cutting edge for forward & reverse machining

- Modifications available at short notice

-

Various activation mechanisms (e.g. bump style, torque bar, etc.)

-

Ideal for interrupted cuts

-

Edge position sensoring system

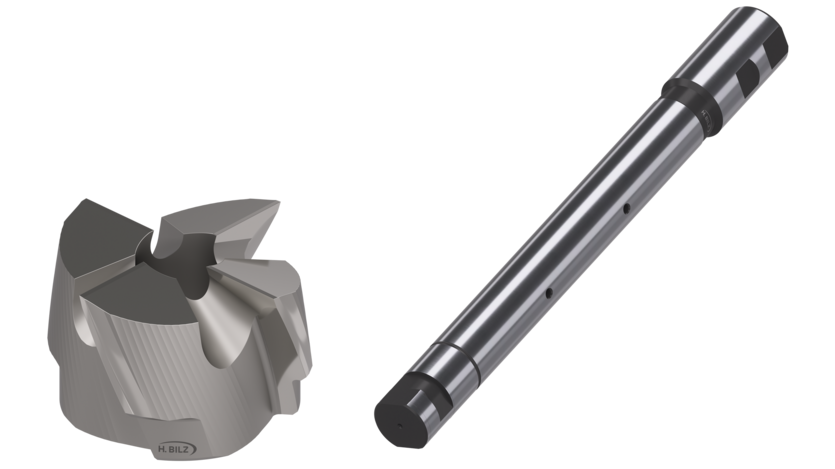

The TU back counterboring system covers a wide diameter range and, thanks to its modular components, can be adapted to many applications. TU is ideal for users who need flexible, reusable base holders and interchangeable cutting heads. Special designed versions allow custom diameter combinations, cutting geometries, indexable-insert designs, lubrication grooves as well as multi-step and special forms.

Back counterboring system TU

The RFS back chamfering bar is designed for back chamfering in the diameter range Ø 15–31 mm and combines high stability with internal coolant. It is particularly suitable for components with medium bore sizes where chamfers on the back side must be produced safely and repeatably. Special designed versions include custom diameter combinations, freely definable chamfer angles and application-specific insert geometries.

Back chamfering bar RFS

The chamfermill FUN enables double-sided deburring starting from very small bore diameters and significantly reduces machining time. It´s ideal wherever many small bores must be deburred with very short cycle times – for example in series production of hydraulic valves, precision components and fine-mechanical parts.