Drilling into solid – Precision drills in solid carbide and with indexable inserts

With our tools for drilling into solid material, you achieve precise, process-reliable holes in steel, cast iron, aluminium and many other materials – from high-volume production to demanding single-part machining. Whether high-performance solid carbide drills, indexable insert drills or fine boring tools for tight tolerances: Hermann Bilz offers a comprehensive drill portfolio and supports you with fast response times whenever you need help in a hurry.

What is meant by drilling into solid material?

Drilling into solid material means producing a hole directly from solid stock, without a pre-drilled pilot hole. The focus is on reliable chip formation, coolant supply and tool guidance to ensure:

- accurate hole diameters

- straight hole paths

- defined hole tolerances and surface qualities

Depending on diameter range, hole depth, workpiece material and machine capability, you will use either solid carbide drills or indexable insert drills. For holes with increased demands on tolerance, roundness and surface finish, fine boring tools complete the range.

Benefits of drilling into solid material with Hermann Bilz tools

With Bilz drill systems you benefit from:

- High productivity thanks to optimised cutting geometries and high feed rates

- Process-reliable holes due to guide lands and optimised coolant supply for straight hole paths

- Wide diameter range in standard, extended by special designs

- Universal use in steel, cast iron, non-ferrous metals and many other materials

- Standard tools from stock and special solutions with short lead times

- Support from our application engineering team with tool selection, cutting data and process optimisation

Drill systems at a glance

For different diameter ranges, drilling tasks and production volumes, Hermann Bilz offers three coordinated drilling concepts with several drill families:

- Drilling with indexable inserts

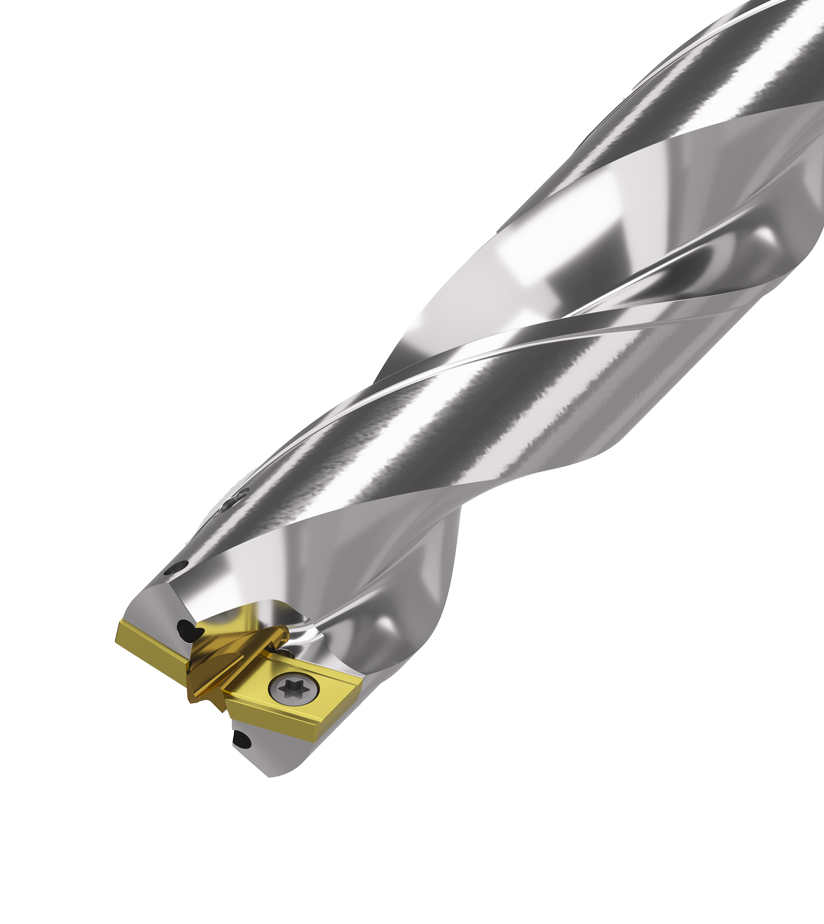

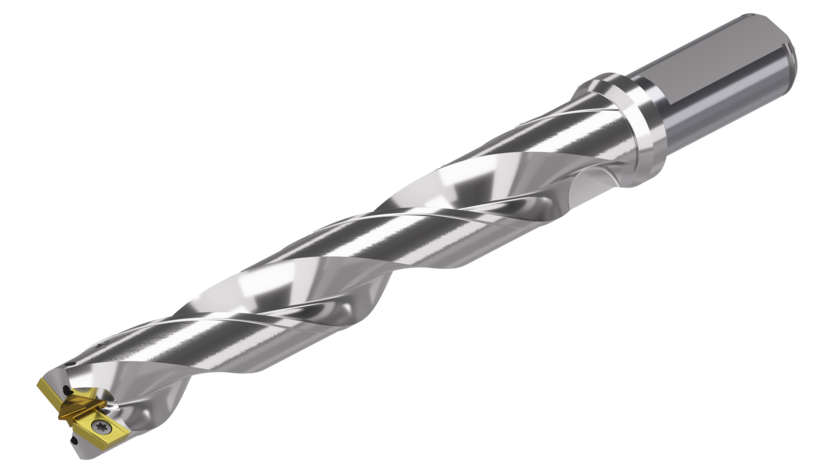

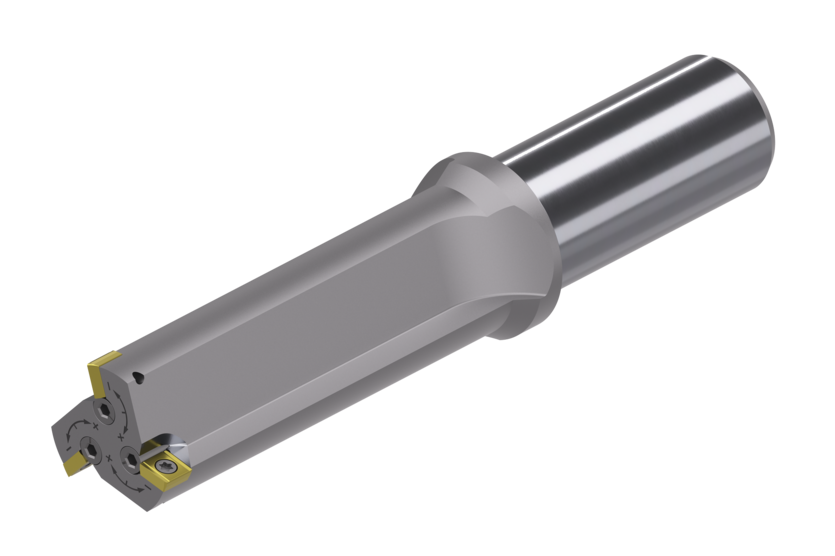

- Flexispeed – indexable insert drill for Ø 18–39 mm, self-centering with HSSE pilot, high feed rates and tolerances up to H11

- KSB Powerbore – indexable insert drill for Ø 39–160 mm, high toughness in the centre, large cutting widths and tight tolerances

- Drilling with solid carbide

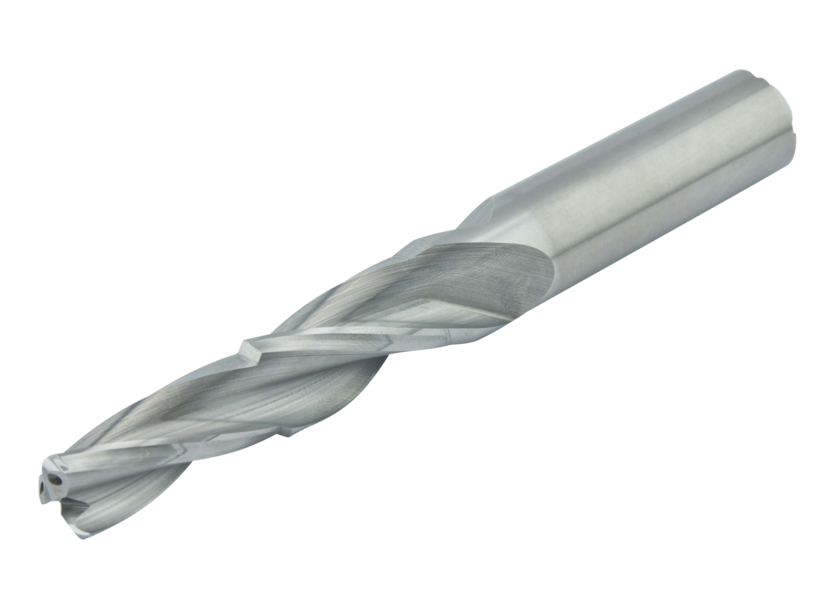

- Precispeed – solid carbide drill programme for precise holes without pilot drilling, high form accuracy and low-burr hole exit

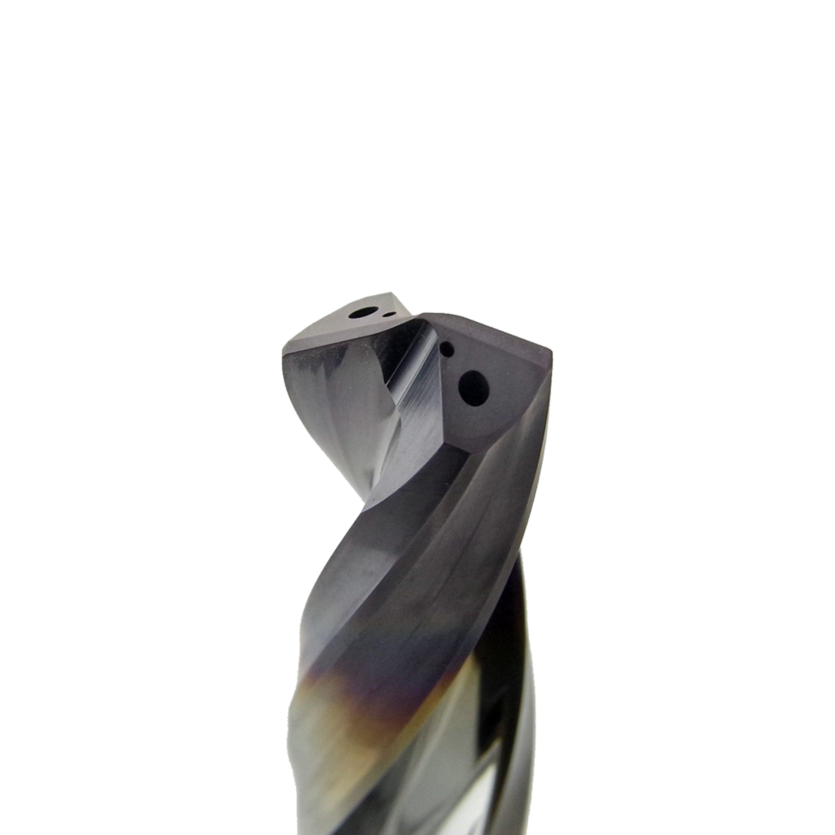

- Turbo-Drill – high-performance solid carbide drill for all common steel grades with maximum process reliability and productivity

- Bilz Rapid – fast-delivery solid carbide drills (Ø 5–25 mm) for steel, cast iron and aluminium, also available as step drills or with 180° flat point

- F-Drill – flat drill for inclined entry surfaces and flat-bottom holes

- Fineboring

- MicroCut – fine-adjustable system with backlash-free adjustment and 2 μm setting increments for the highest demands on accuracy and surface quality

- Preci-Cut – system for boring and finishing Ø 18–40 mm with high metal-removal rates and tight tolerances (IT7–8), combined with fast and precise diameter adjustment

Typical applications for drilling into solid

Our drill systems are used in, among others:

- Automotive: holes in engine and transmission housings, flanges, suspension and structural components

- Mechanical engineering: holes in housings, frames, flanges and machine elements

- Hydraulics / pneumatics: through and connection holes in valve and control blocks

- Powertrain and energy technology: holes in shafts, housings and connecting elements

- General plant and fixture construction: wherever solid drilling operations must be performed reliably and economically

Engineering, design & standards

For optimum design of your drilling tools we take into account:

- hole diameter, depth and position

- workpiece material and required hole quality

- machine type, spindle interface and fixturing concept

- available coolant and lubrication strategy (through-coolant, emulsion, oil)

- required tolerances, surface values and cycle times

Our application engineering team supports you with:

- selection of the appropriate system (Turbo-Drill, Bilz Rapid, KSB Powerbore, Flexispeed, fine boring tools, MicroCut)

- design of grade, coating, number of cutting edges and geometry

- recommendations for cutting data on your machine

- evaluation of process stability and tool life

The more complete your information, the faster we can provide a suitable tool recommendation.

Flexispeed

Standard range

- Solid drilling Ø 18–39 mm

- Self-centering HSSE pilot cutting edge

- High feed rates possible thanks to two effective cutting edges

- Tight hole tolerances up to H11

- Guide chamfers for straight holes

- Universal use with carbide and HSSE indexable inserts

- Suitable even under unstable machining conditions

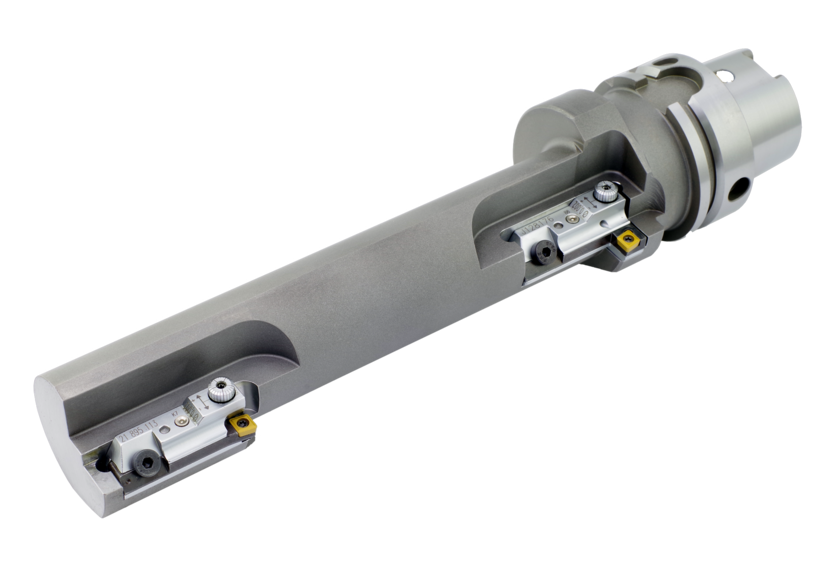

Powerbore KSB

The modular indexable insert drill!

Standard range

- Solid drilling from Ø 39–160 mm

- High feed rates due to maximum insert overlap

- Reduced spindle power requirement thanks to highly positive cutting geometry

- High toughness in the centre during entry

- Tight hole tolerances up to H11

- Guide chamfers on the inserts for straight holes

- Guide pads for angled exits and interrupted cuts (KSB03)

- Also suitable for less rigid machining conditions with HSSE inserts

- Suitable for stack drilling as well

Custom designs

- Custom diameters on request

- Effectively two cutting edges for maximum feed on powerful machines

- Step drill versions for complete machining in a single operation

- Designs for drilling depths up to 1000 mm

Special requestProdukt configurator

Does your machine have sufficient power?:

Precispeed

The special solid carbide drill without a chisel edge

Turbo-Drill

The solid carbide high-performance drill for steel

Bilz Rapid

The solid carbide express solution when timing is critical!

F-Drill

Flat drill for inclined entry surfaces

Preci-Cut RPC

Standard range

- Boring and finishing from Ø 18–40 mm

- Tight hole tolerances (IT7–8)

- Fast and precise diameter adjustment

- Cutting widths up to approx. 4 mm

- Standard diameters available from stock

- Universal use on rigid machines

- Compatible with numerous carbide and cermet indexable insert variants

- Indexable inserts with ground guide lands minimise chatter and produce smooth surfaces

Do you already know our full product range?

We are your competent partner for:

drillinginsertscounterboringshrink fitback counterboringspecial request